Z-Flex Multilayer Aluminized Fabrics

Compare & Quote This Product

Gentex Dual Mirror Aluminized Fabrics

Tell Me MoreWATCH How Z-Flex Compares to Competitive Aluminized Fabrics

Tell Me MoreInterested in Custom Heat Shields?

Tell Me More*** NEWTEX HAS ACQUIRED THE DUAL MIRROR® PORTFOLIO ALUMINIZED PORTFOLIO FROM GENTEX ***

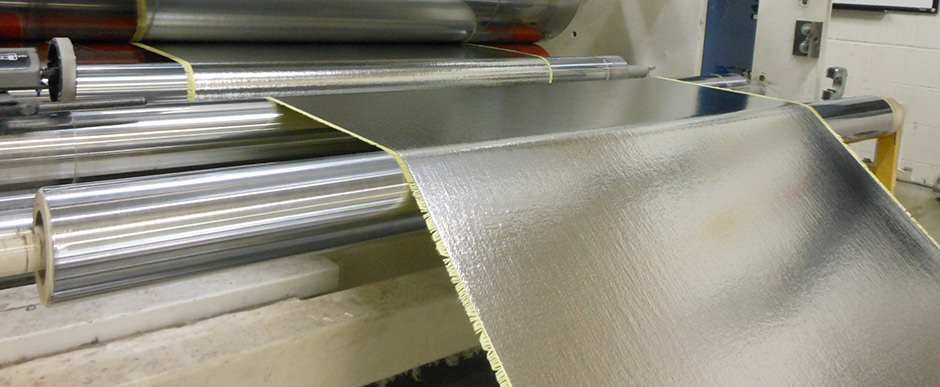

Advanced Aluminized Fabrics for Fire Fighting, Industrial Safety and Heat Shielding

Aluminized Fabrics are engineered to reflect radiant heat in the most extreme work environments, and are used extensively in industrial safety apparel, proximity suits, and heat shields used in high-temperature environments like metal casting, glass forming, and industrial firefighting operations. These flame-resistant aluminized fabrics protect from high temperatures, radiant energy, flames, sparks, and molten metal splash.

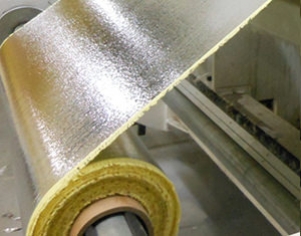

Newtex is very excited to have acquired the legendary Dual Mirror line of Aluminized fabrics to its Z-Flex Aluminized portfolio, creating the most comprehensive offering of radiant protection available globally. Dual Mirror® Aluminized Fabrics expand our range of capabilities, and feature Korspun Aramids, Preox, and Preox/Korspun blends with a specific focus on Safety Apparel applications.

https://shop.gentexcorp.com/aluminized-fabrics/

Z-Flex® Aluminized Fabrics are available in a variety of styles including aluminized fiberglass, aluminized aramid (commonly known by the brand name Kevlar®), and aluminized rayon. Because of our proprietary aluminized film and aluminization process, these high-temperature aluminized fabrics offer outstanding reflectivity, durability, and flex-bond. Unlike competitive aluminized fabrics, we use an inherently fire-retardant adhesive in our aluminization process. This fire retardant adhesive withstands high temperatures longer than competitive fabrics, leading to more durable and protective proximity suits and eliminating concerns about de-lamination.

Both leading brands reflect up to 95% of radiant energy and protect from high temperatures and radiant heat up to 3000°F / 1650°C however, the aluminized surface is not designed for direct contact with temperatures above 350°F / 175°C. The Z-Flex® and Dual Mirror® Aluminized Fabrics have been independently tested against the most demanding US & EN standards and have proven to consistently deliver superior heat shielding performance against competitive offerings.

Testing in accordance to:

- Radiant Heat Testing: ISO 6942, EN 366, ASTM F1939

- Convective Heat Testing: ISO 9151, EN 367

- Limited Flame Spread Testing: ISO 15025, EN 532

- Molten Metal Testing: ISO 9185, EN 348, ASTM F955

- Abrasion & Tear Resistance Testing: ISO 13937, EN 388

Products

Z-Flex Silver

These NFPA 1971 certified fabrics are specifically engineered for ARFF personnel and specialized firefighters.

Z-Flex Air

These breathable aluminized fabrics provide the same radiant heat protection as the original Z-Flex.

Z-Flex Aluminized Fiberglass

Aluminized fiberglass fabrics are designed for superior insulation and radiant heat protection.

Z-Flex Aluminized Aramid

Aluminized aramid fabrics deliver strength, abrasion resistance, and radiant heat protection

Z-Flex Aluminized Rayon

Aluminized rayon fabrics deliver radiant heat protection, burn protection, and flexibility.

Z-Flex Aluminum Foil Fabric

Foil fabrics are a low-cost option for static heat shielding applications.